Machine Condition Monitoring System

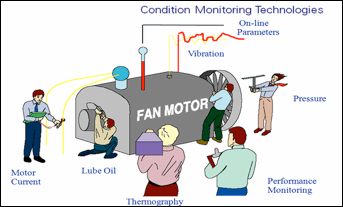

Condition monitoring systems (CMS) monitor equipment degradation over a Period of Time and we Provide Solution for Predictive Maintenance System. For predictive Maintenance a Continuous Measurement of Speed, Torque, Vibration, Noise, Oil Quality, Acceleration, Velocity, Power consumption include Motor voltage and Current of any machinery/Equipment is Monitored. Whenever Values Reaches the Threshold Limit, An Alarm Is generated for Quick Action. Our CMS System is also used for Diagnosis and troubleshooting after Machine Failure. We Provide Both Online/Offline and Portable as well as Monitoring System for complete Shop Floor.

CMS offer Various Advantages. Maintenance, operations, and reliability engineers and technicians rely on condition monitoring and predictive maintenance techniques to ensure critical equipment such as turbines, generators, pumps, compressors, and motors operate more efficiently and last longer.

We offer a ready-to-run integrated hardware and software solution for online condition monitoring System thus helping companies to gain insight and improve operations and maintenance programs by understanding the health of rotating machinery. The System acquires and analyzes measurements, generates alarms, gives users the ability to visualize and manage data and results, and simplifies remote management for large numbers of monitoring systems.

• Built-in analytics and alarming capabilities, and remote interactive visualization of waveform data.

• Easily scalable to hundreds of acquisition devices per server.

• Support for vibration and process measurements using integrated hardware options.

• Remote management of monitoring systems and users.

• IT-friendly security features include user and device authentication.